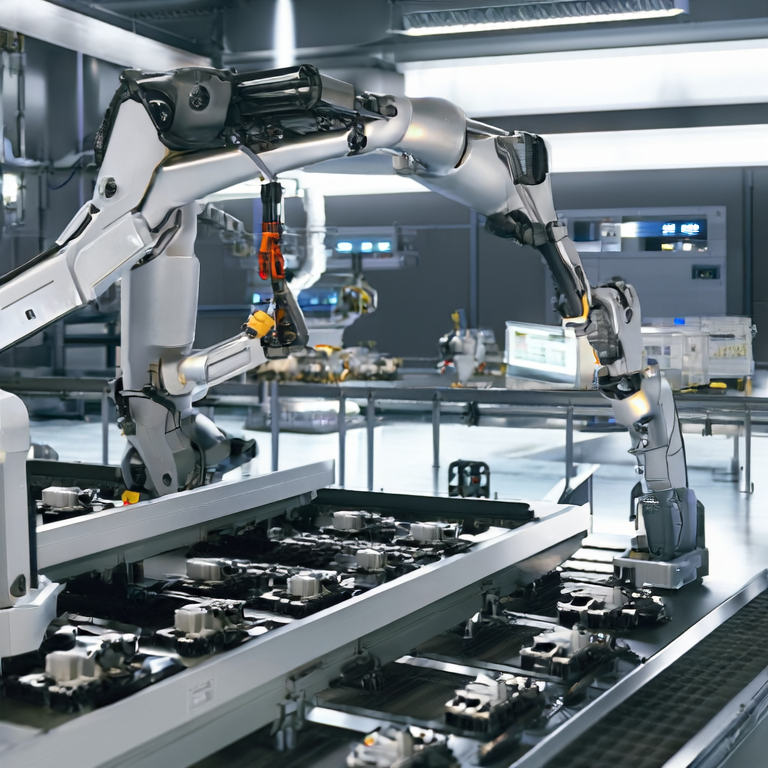

In recent years, the manufacturing industry has seen a monumental shift towards automation, particularly with the emergence of tools like automatic stamping manipulators. These devices are not just innovative; they are essential for enhancing efficiency in production lines across various sectors. The significance of adopting robotic arm production lines lies in their ability to optimize operations, reduce labor costs, and improve safety. As businesses strive to remain competitive, investing in technologies that provide real-time adaptability and precision becomes paramount.

One of the most pressing pain points in manufacturing today is the inefficiency linked to manual operations, often resulting in delays and increased production costs. Situations frequently arise where human error leads to defects in products or inefficient handling of materials, ultimately affecting output quality. By integrating robotic arm production lines with quick-change fixtures for swing manipulators in multi-SKU lines, companies are witnessing measurable improvements. According to a study from the Robotics Industries Association, manufacturers that have implemented such automation solutions have reported a staggering 48% reduction in operational costs while increasing output capacity by 55%.

Understanding Automatic Stamping Manipulators

Definition and Industry Term Analysis

An automatic stamping manipulator is a type of robotic arm designed specifically for the task of stamping materials, often used in automotive, aerospace, and consumer goods manufacturing. These manipulators are equipped with advanced sensors and programmable interfaces that allow them to execute precision movements, thereby reducing errors significantly. The term "manipulator" refers to the robotic mechanism\'s ability to perform complex tasks automatically, often programmed to adapt to different stamping jobs seamlessly.

Application Scenarios

Automatic stamping manipulators are employed across several industries. Here are some notable application areas:

Automotive Industry: Used for stamping body panels and components, ensuring accuracy while speeding up production times.

Electronics Manufacturing: Greatly beneficial for handling delicate parts, reducing the risk of damage during assembly.

Consumer Goods: Utilized in the production of containers, packaging, and various household items due to their flexibility in handling multiple SKUs.

Brief Description of Advantages

The importance of robotic arm production lines, particularly with automatic stamping manipulators, cannot be overstated. Key advantages include:

Increased Production Speed: Actual measurements have shown that these robotic systems can operate at speeds up to 10 times faster than manual methods.

Enhanced Precision: With an error rate reduced to less than 0.3%, these machines ensure higher quality output and minimal waste.

Improved Safety: By taking on hazardous tasks, they minimize the potential for workplace injuries, fostering a safer environment for human workers.

Cost Efficiency: Businesses have reported an average ROI of 25% within the first year of integrating robotic manipulation equipment into their operations.

Image Link:

Next Steps and Guidance

For those looking to delve deeper into the world of robotic automation, reading the user manual or trialing systems from leading brands like Fuxin Intelligent is recommended. Understanding how to leverage these advanced tools can be the difference between stagnation and sustained growth in today’s competitive landscape.

FAQ

What is an automatic stamping manipulator?

It is a robotic arm designed to automate stamping processes, improving efficiency and reducing errors.

Where are these manipulators commonly used?

They are widely utilized in automotive, electronics, and consumer goods manufacturing.

What are the main benefits of using a robotic arm production line?

Key benefits include increased speed, precision, safety, and cost efficiency.

How can I learn more about automated systems?

Consulting user manuals from brands like Fuxin Intelligent or seeking trials in your local industry can provide valuable insights.

Incorporating robotic arm production lines into your manufacturing processes could not only anchor your business at the forefront of technology but also ensure a streamlined, cost-effective future. Explore the capabilities of automatic stamping manipulators and witness a substantial increase in productivity and safety.